ISQapave Welding Qualifications

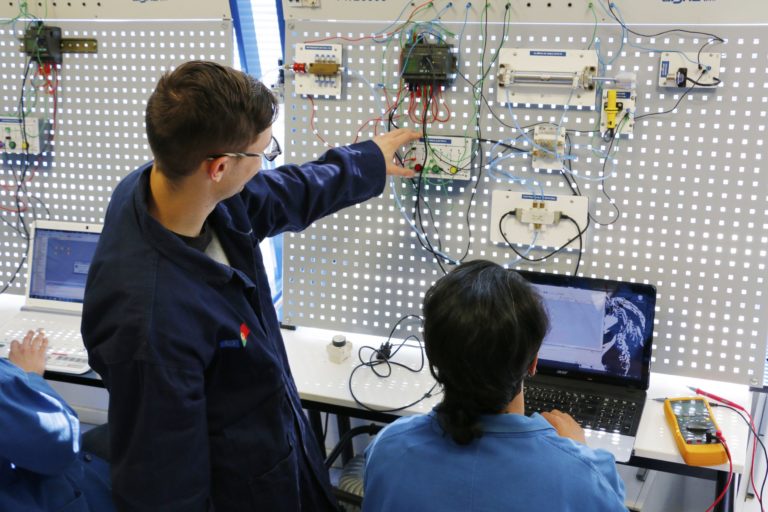

With the main focus on market Oil & amp; Gas the ISQapave has had over the past few years actively involved in the area of welders qualifications and welding procedures qualifications in the oil market in Angola having already participated among others in the following major national major projects:. Clov Pazflor greater Plutonium PSVM Kizomba Satellites and West Hub

In close collaboration with major construction companies operating in onshore / offshore Angola – Friedlander Ponticelli / Portumo GE Oil & amp; Gas; Oceaneering among others – the ISQapave qualified in 2014 about 160 welders and until August 2015 more than 130 welders in the vast majority of Angolan nationality .

In response to the market logic of the ISQapave has contributed to the development of specifications and qualification of welding procedures .

For the inherent welding materials employed in the oil industry – steel carbon austenitic stainless steel duplex stainless steel alloy of copper-nickel combination of stainless steel with nickel alloys (inconel) among others – qualifications are implemented in accordance with the rules and codes EN 15614-1 / EN 9606-1 ASME IX AWS D1.1 and API 5L complemented with the requirements set out in the technical specifications of the oil operators.

At issue is the response to projects involving the welding of crude water extraction lines injection lines welding the riser tubes (tubes that connect the drilling rigs Drilling Rig to FPSO production units) production monitoring lines of control units (Christmas trees small bores) platforms and structures (top sides) among others.

At the same time the ISQapave celebrates 10 years of presence in Angola also leads the activity of welding qualifications in the oil market .