Innovate on the way to Industry 4.0

ISQ has four decades of experience in technological development involving national and international partners. Innovation has been the beacon of ISQ in its journey and collaboration with scientific, technological and business entities the privileged means of exploring synergies and added value that have led ISQ to a high level of relevance in the industrial context.

by Helena Gouveia and Ana Cabral

Innovate with ambition

“do more with less.”

The phrase reads on the website that presents the MAESTRI project, an initiative that brings together a large European consortium around an ambitious goal. What is intended is the development of an ” integrated system of energy and resources management in industry, based on innovative methodologies for characterizing the efficiency of industrial processes, on strategies of incorporation of the principles of eco-efficiency and continuous improvement throughout the organization.

It is up to ISQ to ensure the coordination of this project, as part of the Horizon 2020 funding programme, which brings together some of the most prestigious European institutions in the area of R&Di. By taking over the coordination of this project, ISQ evidenced the capabilities it has acquired over decades: technical competence, commitment to innovative solutions and leadership profile.

MAESTRI

European research and development project aimed at creating an integrated energy and resource management system, with the aim of developing and applying methodologies to promote eco-efficiency in industry: “doing more with fewer resources”

ISQ coordinates a consortium of 15 European partners from 5 Member States (Portugal, Germany, Italy, Poland and the United Kingdom).

The MAESTRI, developed in the context of The R&Di activity, is one of the best examples of the ongoing effort, in

Portugal and in the world, to adapt the management and production processes to the challenges of the so-called Industry 4.0.

An evolution that involves not only the use of technology to improve the way of producing – increasing efficiency and reducing costs – but also to ensure the objectives of sustainability and respect for environmental values.

In the area of Industry, ISQ’s strategy to strengthen its technical-scientific excellence and support companies in increasing their technological maturity was to invest in the development of new knowledge and demonstrate existing R&Di results in industrial applications. Hence the focus on Artificial Intelligence, Big Data and Data Analytics, where it will continue to invest resources, due to its vital importance in the new industrial paradigms.

In this context, the main strategic lines of research have focused on robotics and process automation, the development of advanced materials processing technologies or the development of applications using virtual and augmented reality technologies.

ISQ’s strategy to enhance technical-scientific excellence and support companies was to develop new knowledge and demonstrate R&Di results in industrial applications.

ISQ’s performance has been understaken by technological trends, also taking into account national and European policies and strategies and competitiveness and employment objectives. In this work, ISQ has a multidisciplinary team of researchers where engineering predominates, as basic training, especially in the fields of mechanics, materials, electronics and chemistry. About half of the researchers are masters or doctorates.

In the current I&Di organization, the Industry sector is worked on by all four of its R&Di units: Low Carbon and Resource Efficiency; Materials and Technologies; Intelligent and Digital Systems and Training and Qualifications.

A journey made up of partnerships

ISQ’s investment in R&D began in the late 1970s, with the creation of its own department, partly the result of important investments in advanced human resources training at prestigious European universities and the French Welding Institute.

At an early stage, ISQ’s R&D projects fell into the areas of materials, welding processes, mechanical and non-destructive testing, areas that corresponded to the institute’s core competencies and the needs of the market at that time. Portugal’s support of the European Community has brought a wide range of opportunities.

SCALER

Increase the adoption of Industrial Symbiosis (IS) in Europe. Innovation consists in the production of tools and methods aimed at various stakeholders in order to facilitate the identification of potential, feasibility analysis and implementation of synergies that allow collective management of resources and waste. One of the objectives is the design of a database of IS enabling technologies.

ISQ coordinates the project, in which the University of Cambridge, University of Chalmers, Climate KIC, STRANE Innovation and Quantis participate.

ISQ has started to participate in various European Funding programmes, from the ECSC -European Coal and Steel Community to the BRITE/EURAM programme and, of course, the various European Union Framework Programmes that followed it, from the 4th Framework Programme to the current Horizon 2020.

ISQ’s significant investments in R&D activities reveal the increased importance this area has been gaining, not least because it represents an increased effort for the organization when it comes to project coordination, which has been increasingly happening. In these cases, the taking on of the coordinating role is assessed taking into account the added value, reputation and impact that the project may bring.

SIM 4.0

Intelligent Monitoring Systems

The SIM 4.0 project, presented and financed within the scope of the Support System for Collective Actions – SIAC, has as main objective to transfer scientific and technological knowledge to the industrial fabric, thus contributing to fill some gaps in information and knowledge about advanced technologies and its application in industrial systems.

Participation as a partner in R&D initiatives at the invitation of external entities is always evaluated on a case-by-case basis. The objective of this participation may be focused not only on development and innovation, but also on technical-scientific training, positioning in new markets and geographies and creating new strategic partnerships.

R&D activity over the past four decades has thus created a vast network of national and European partner entities, which includes universities, polytechnic institutes, scientific and technological entities, public authorities, technology producing companies and users in different industrial sectors, as well as with companies developing new solutions. This permanent connection with the most important players in the sector has allowed ISQ to keep track of new technologies, methodologies and products.

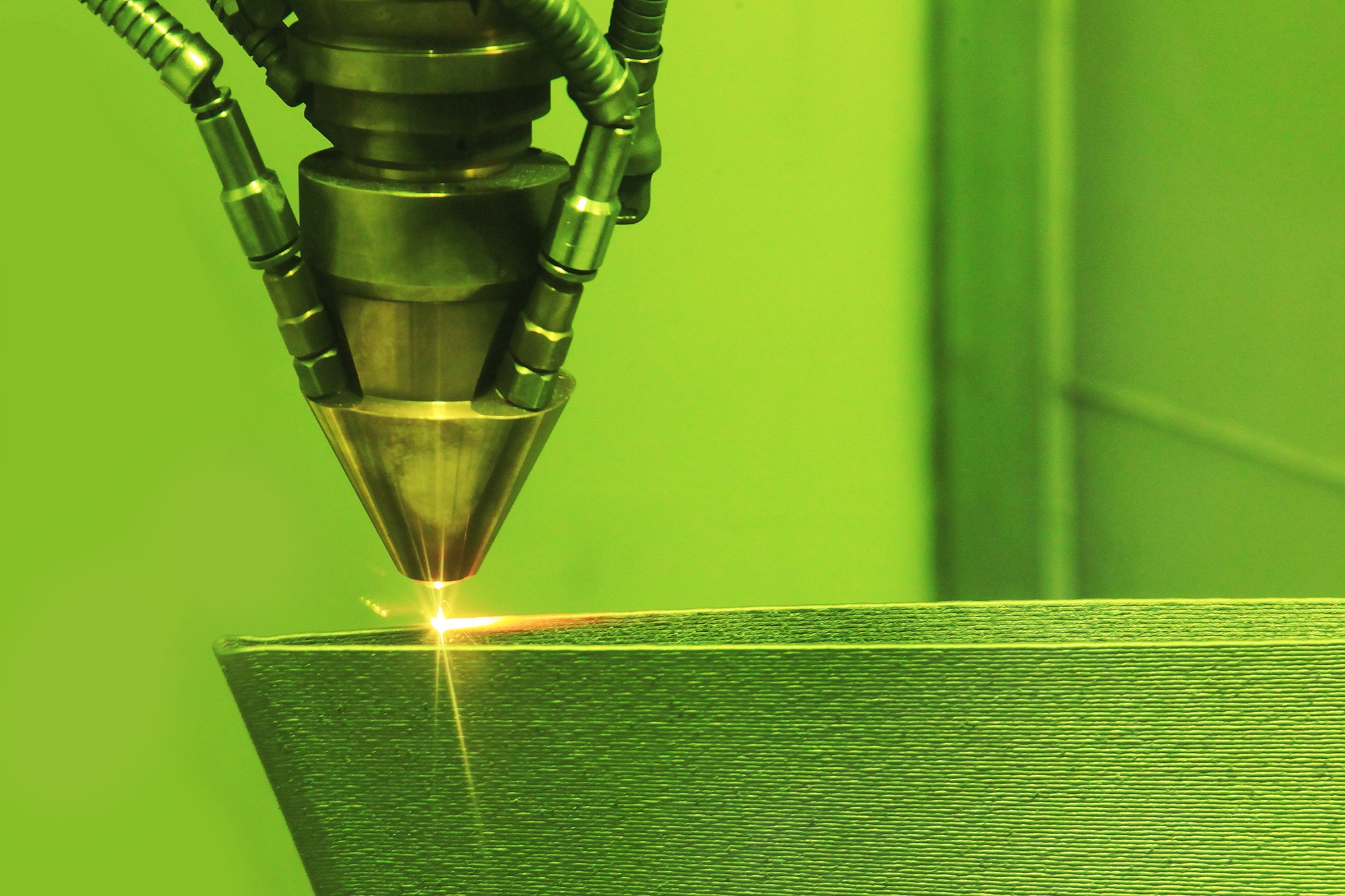

INDUSTRIAL 3D PRINTING

ISQ IN ADDITIVE MANUFACTURING

MULTI-FUN: Multi-functional performance through additive manufacturing

The main objective of the project is to promote a significant gain in performance and efficiency in metallic additive manufacturing products through the complete integration of multi-functionalities. Furthermore, the project will allow the design of various materials into geometrically complex 3D metal parts without size limitation by innovative and cost-effective additive manufacturing technologies.

HIPA2L: High Performance Additive manufacturing of Aluminium alloys

ISQ was invited to join the HiPA2l (High Performance Additive manufacturing of Aluminum alloys) project, which aims to develop new aluminum alloys, intended for manufacturing processes or additive manufacturing, in the form of welding wire, for the construction of components. layer by layer.

SAM: Sector Skills Strategy in Additive Manufacturing

The SAM project aims to develop technical skills to qualify young people interested in working in the additive manufacturing sector in Europe. The project aims to define a qualifications strategy for this sector, including techniques such as 3D printing.

+ insight

contribute

As a project initiated by ISQ, insight is open to contributions from everyone who wants to participate and who can bring their vision, scientific studies and reasoned opinion to enrich the themes and the debate.

If your activity is linked to research or the analysis and implementation of measures in the topics discussed here, please contact us using the form attached.