Ecodesign in the aerospace industry

One question arises under the European Space Agency’s (ESA) Clean Space initiative: “What happens when you try to apply EcoDesign to the aerospace industry?”

What happens when you try to apply EcoDesign to the aerospace industry?

This is in terms of the environmental impacts and legislation to be complied with by ESA’s programmes.

EcoDesign and Life Cycle Evaluation (LCA) are methods recognized as applied in concepts such as eco-efficiency or “cleaner” production.

In practice, EcoDesign provides a logical structure that, with the support of environmental information generated by a LCA, allows identifying the main environmental challenges of a given product or manufacturing process and, consequently, supporting the identification of potential compromise solutions.

What are the main challenges of adapting ecodesign tools to demanding applications such as those in the aerospace industry?

That is why the question “What happens when you try to apply EcoDesign to the aerospace industry?” arises under ESA’s Clean Space initiative, which provides for establishing a common framework for the European space sector with regard to the assessment of environmental impacts and compliance with existing legislation by ESA programmes. As a main result, Clean Space foresees the development of an Ecodesign tool, to be integrated into its planning process, to include the environmental aspect in the planning of future space missions.

The main problem stems from the fact that existing tools are specific to in-application technologies, with a major emphasis on general consumer products and large-scale production practices. Therefore, the correct functioning of this tool clearly depends on the inclusion of the specificities of this sector, which, among others, include the use of single materials, specialized manufacturing processes, lower production volumes or tests and more demanding functional requirements.

In this sense, the question now arises: “What are the main challenges of adapting ecodesign tools to demanding applications such as those in the aerospace industry?”

As a first response attempt, ESA has launched an invitation to carry out Life Cycle Assessments (LCA) for a wide range of materials, components and manufacturing processes specific to this sector, a work in which ISQ participated and from which the main conclusions are presented.

Main conclusions

Most materials used in demanding applications are not properly modeled by current tools.

This conclusion is evident in the vast majority of components and processes analyzed, with special focus on those using materials with specific properties. An excellent example is high strength aluminum alloys, such as so-called light alloys or aluminum-lithium alloys.

The results clearly show that small differences in alloy composition can lead to significant variations. In fact, some of the elements present in this type of alloys can contribute very significantly, even if they are in low concentrations. This is therefore a challenge for the application of Ecodesign in advanced applications, as it is expected that applications that require specific properties, obtained by special alloys, present results substantially different from those provided by current tools.

The use of specific materials leads to more emissions in the production phase.

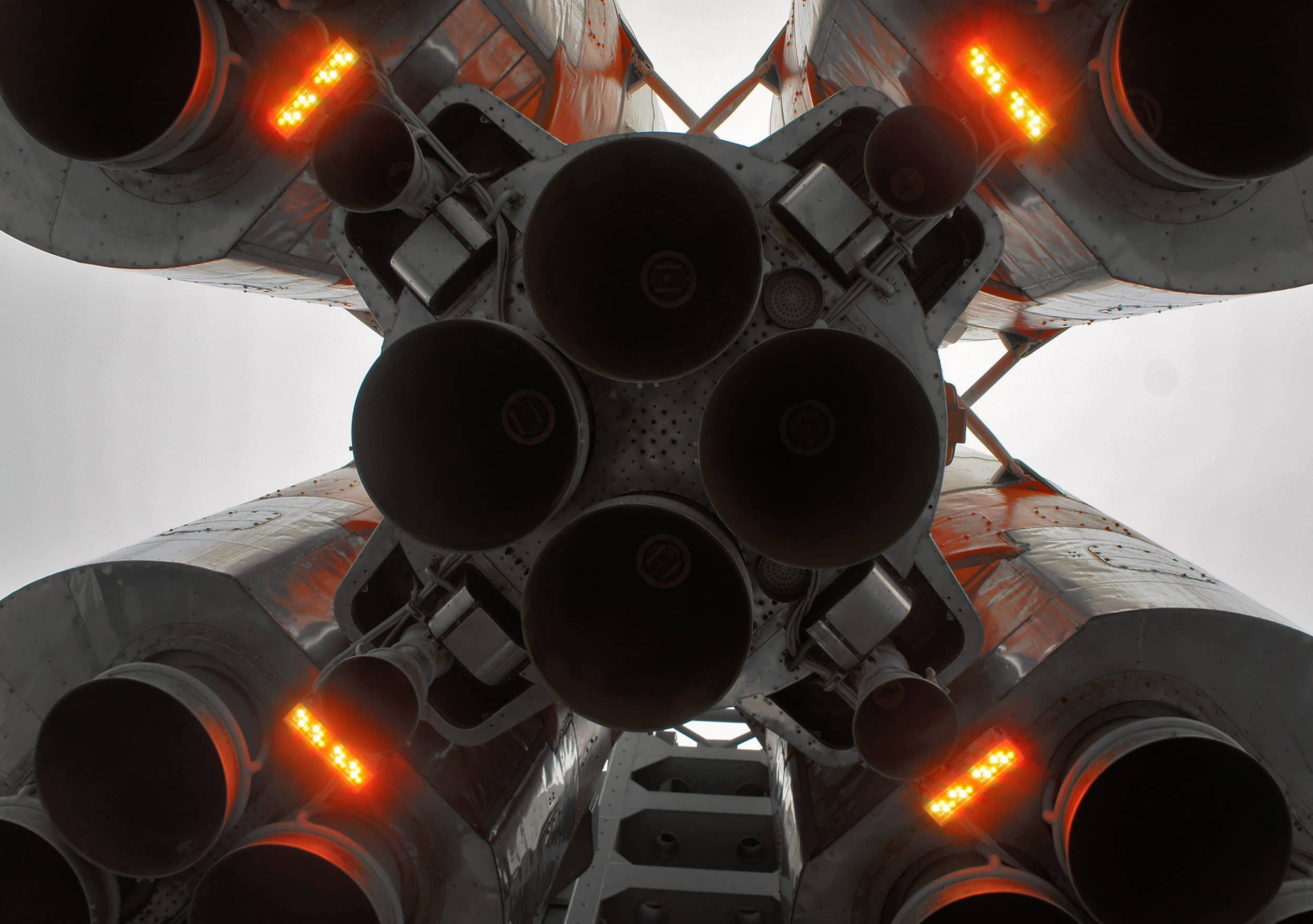

The efficient use of materials is especially important in demanding applications. An example of this are components made from titanium alloys, such as propellant storage tanks, in which material removal rates can amount to 95%, regardless of the geometry of the propellant. For example, we can talk about the environmental assessment of the production of a cylindrical tank of 1m3, covered with carbon fiber, whose main message here is that the environmental performance of the production of this type of components is clearly dependent on the recovery of the base material, more than any process support structure or energy consumed.

In this sense, it is recommended to use materials with closed recycling cycles, with special focus on those in which the properties of the materials are maintained after the recycling process.

The risk of supply chain rupture may occur indirectly.

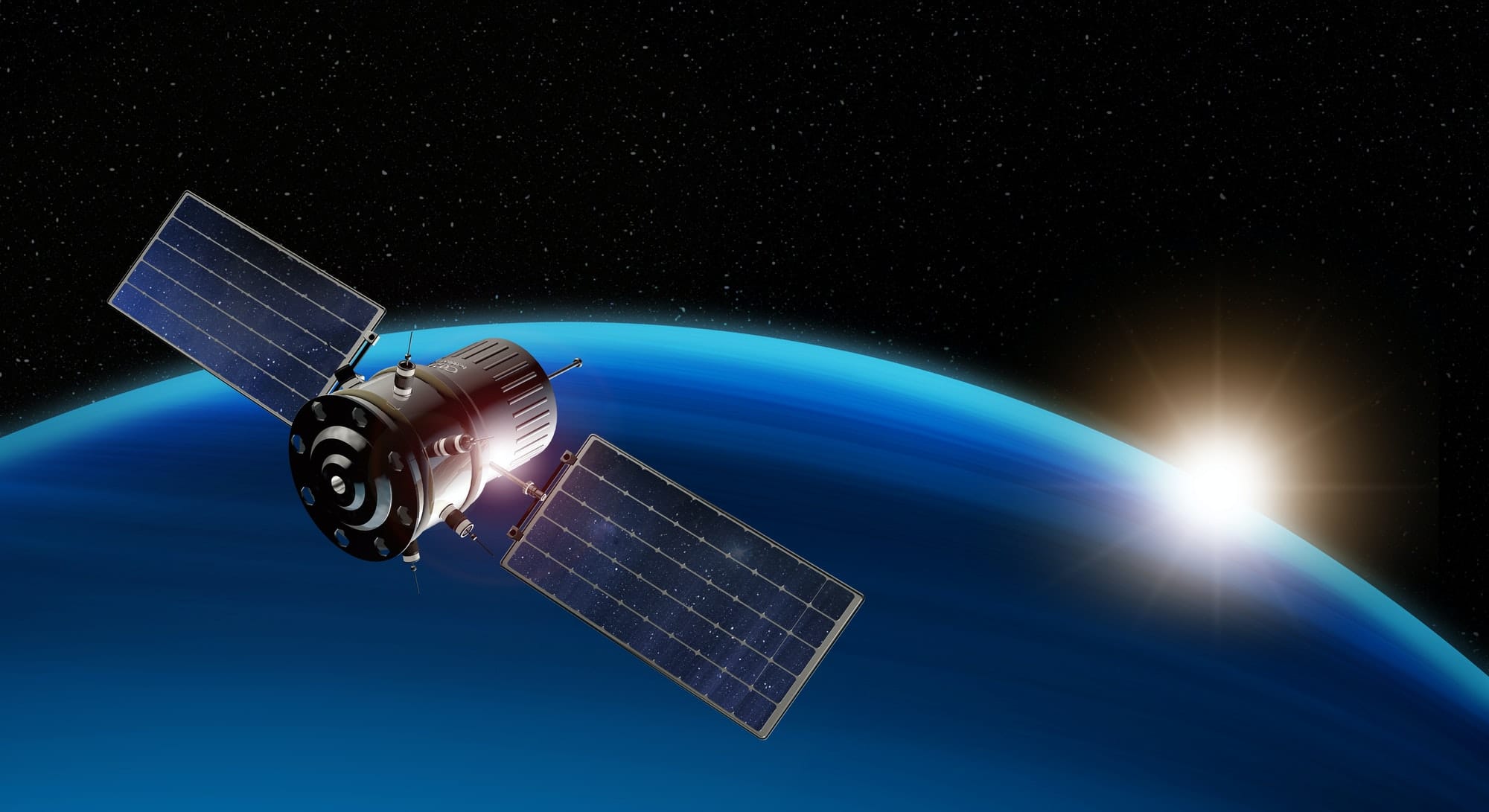

The dependencies of essential raw materials can also occur, indirectly, from the use of materials in supporting functions. The main example is the fluorite used in the production of Germanium, the base element of photovoltaic panels used in space missions.

With regard to the production of photo-voltaic energy, the currently most used system corresponds to triple-junction solar cells composed of two layers of Lyo-Indio-Phosphorus and Arsenic-Gálio-Arsenium supported in a structural layer of Germanium. Its use is fundamentally justified by greater efficiency, advantages in radiation and hardness, small temperature coefficients, high reliability, high voltage and low current.This is clearly one of the advantages of using LCA methodologies, as it facilitates the identification of particularities existing in the various steps upstream and downstream of the process or product under analysis.

In quantitative terms it was also possible to conclude that, for example, for the production of a germanium layer with an area of 1m2 and a thickness of 150μm, 7.1kg of fluorite is required.

Small amounts can contribute to a large extent.

As has been the case in the production of different alloys or photovoltaic panels, small variations in materials or concentration can lead to discrepant results and, consequently, to erroneous conclusions. Therefore, considering the specificity and uniqueness of many of the materials used by the aerospace industry, it is recommended that all elements present in the composition of any component be considered, aiming to obtain results that reflect their real environmental performance.

Recommendations

The results indicate that the advanced manufacturing methods used by the aerospace industry add particular properties when compared to conventional ones. In fact, these methods are in most cases associated with lower environmental performance, which does not mean that they should lack an environmentally negative connotation.

In fact, this reflection focused only on sharing ways of taking advantage of Life Cycle Assessment methodologies and EcoDesign practices as decision support tools in this sector.

Therefore, responding to the initial question of the article, it is concluded that supporting decision-making in existing EcoDesign tools can lead to wrong compromise solutions. However, when adapted to the particularities of this sector, they offer a vital vision for the supply chain of materials and manufacturing processes.

Therefore, given this usefulness, although associated with a significant effort, the adaptation of these tools to demanding applications such as those in the aerospace sector is highly recommended. It is a future bet in the face of the demands of the sector.

+ insight

contribute

As a project initiated by ISQ, insight is open to contributions from everyone who wants to participate and who can bring their vision, scientific studies and reasoned opinion to enrich the themes and the debate.

If your activity is linked to research or the analysis and implementation of measures in the topics discussed here, please contact us using the form attached.